UML-TECH agricultural machinery electro-hydraulic control system including cotton picker electronic control system, silage machinery electronic control system, H’’arvest machinery electronic control system, sugar cane machine electronic control system, tractor electronic control system,transplanter electronic control system, baler electronic control system, etc., it is an electro-hydraulic control system program for agricultural machinery covering the whole process of agricultural production.

The system has a high level of informatization, advanced and reliable hydraulic solution, easy to operate, and reduces the labor intensity of the operation greatly;

It can achieve precise control of operation,improving the accuracy and efficiency of operation greatly.

Cooperating with UML-TECH Auto-Pilot System can achieve complex automatic operations. Characteristic

Application models

The overall solution for electric-hydraulic control is optimized and reasonable; Key action proportion control, making the control effect more precise; Efficient power matching algorithm, resulting in lower fuel consumption for vehicles. Self developed high-precision row sensor, combined with row control algorithm, with a maximum matching working speed greater than 10KM/H and a row control accuracy less than 10cm; The header profiling system adopts proportional control, with a system response of less than 100ms and a stubble height accuracy of 2cm.

The overall solution for electric-hydraulic control is optimized and reasonable; Key action proportion control, making the control effect more precise; Efficient power matching algorithm, resulting in lower fuel consumption for vehicles. Self developed high-precision row sensor, combined with row control algorithm, with a maximum matching working speed greater than 10KM/H and a row control accuracy less than 10cm; The header profiling system adopts proportional control, with a system response of less than 100ms and a stubble height accuracy of 2cm.

The system has a high level of informatization, advanced and reliable hydraulic solution, easy to operate, and reduces the labor intensity of the operation greatly;

It can achieve precise control of operation,improving the accuracy and efficiency of operation greatly.

Cooperating with UML-TECH Auto-Pilot System can achieve complex automatic operations. Characteristic

The robot R&D team has strong R&D capability, and the supporting products have independent intellectual property rights.

Provide complete control system solutions, covering all models.

Improve operation performance and reduce labor intensity.

Electric and hydraulic precise control, improving work consistency.

Intelligent + informatization, create intelligent interconnection system for agricultural machinery.

Cotton Picker

6-row self-propelled packaging cotton picker

Electric - hydraulic control total solution

Automatic alignment function

Adaptive walking speed

Header profiling control

Electric - hydraulic control total solution

Automatic alignment function

Adaptive walking speed

Header profiling control

Sugar Cane Harvester

Traveling ratio control

Engine-pump power matching control

Header profiling

Rear axle leveling function

Engine-pump power matching control

Header profiling

Rear axle leveling function

The entire vehicle electric control, equipped with a 10.4-inch intelligent on-board computer, equipped with an acre counter, GPS lock, fault diagnosis, and intuitive viewing of each execution action.

Steering wheel operate ravel, using an electronic steering gear.

The bus operating handle controls key actions, triggers buttons, increases operational comfort, and reduces electrical wiring. One button harvest and transition mode, convenient for users to operate and reduce fuel consumption.

The intelligent control system will complete complex controls such as knife control, cutting control, tire control, conveyor arm control, channel control, cane support control, and three-level cutting control.

The intelligent control system will complete complex controls such as knife control, cutting control, tire control, conveyor arm control, channel control, cane support control, and three-level cutting control.

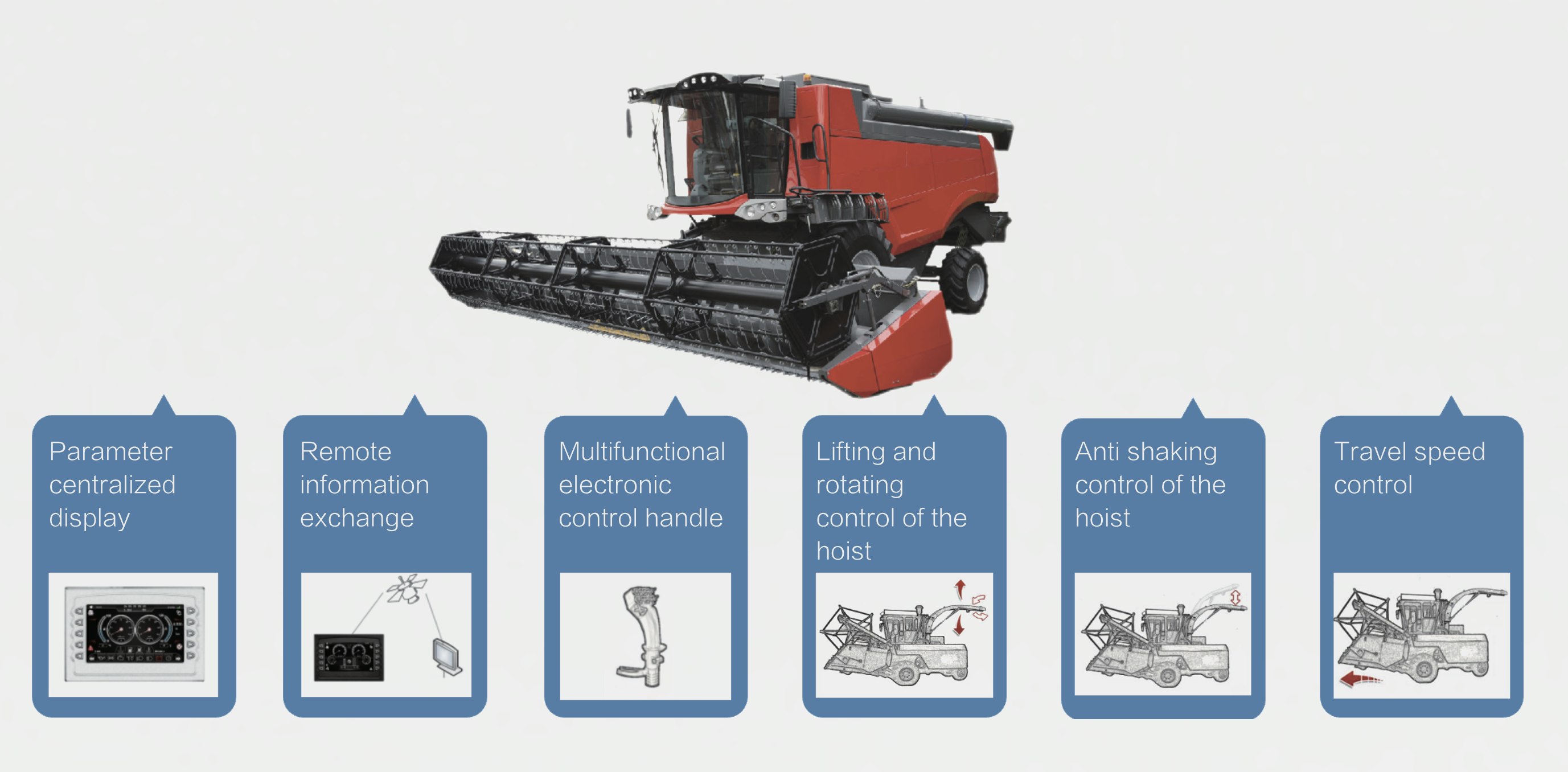

Combine Harvester

Electric - hydraulic control total solution

Vibration reduction of grain unloading drum

Automatically align rows

Header profiling

Vibration reduction of grain unloading drum

Automatically align rows

Header profiling

The overall solution for electric-hydraulic control is optimized and reasonable; Key action proportion control, making the control effect more precise; Efficient power matching algorithm, resulting in lower fuel consumption for vehicles. Self developed high-precision row sensor, combined with row control algorithm, with a maximum matching working speed greater than 10KM/H and a row control accuracy less than 10cm; The header profiling system adopts proportional control, with a system response of less than 100ms and a stubble height accuracy of 2cm.

The overall solution for electric-hydraulic control is optimized and reasonable; Key action proportion control, making the control effect more precise; Efficient power matching algorithm, resulting in lower fuel consumption for vehicles. Self developed high-precision row sensor, combined with row control algorithm, with a maximum matching working speed greater than 10KM/H and a row control accuracy less than 10cm; The header profiling system adopts proportional control, with a system response of less than 100ms and a stubble height accuracy of 2cm.

ROUND BALERS

Non-stop electro - hydraulic control solution

Baling pressure adjustment

Automatic switching of the cutting tool

Process automation